- Obi Creation process

-

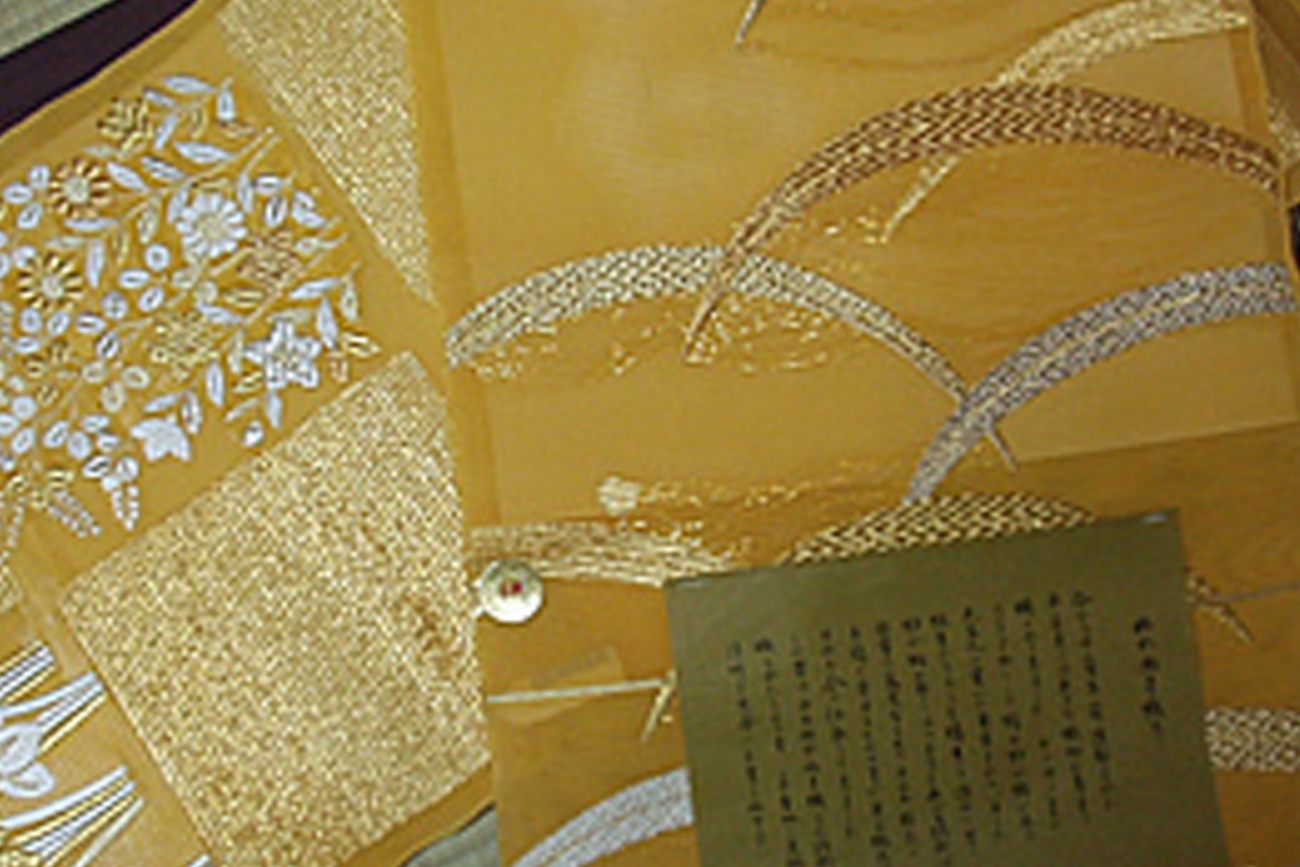

[Pattern Design Blueprint]

The design blueprint for textiles is called a mon-ishou-zu. It starts with a design, which is then detailed on graph paper, showing how to weave the fabric. This blueprint serves as the guide for creating the next set of instructions for the weaving process. As with kimono, starting with an underdrawing to decide the pattern is crucial, especially as more complex designs require meticulous planning.

-

[Pattern Paper (Mon-gami)]

Pattern paper is thick paper perforated accordingly to the design, which instructs the lifting and lowering of warp threads during weaving. These sheets are connected like a caterpillar and set into a Jacquard machine. As you could see in the photo,the Jacquard’s is located at high position and this makes it a challenging task.

-

[Mongami]

Mongami is a thick paper with tiny holes. Those tiny holes guide the raising and lowering of the warp threads to create patterns indicated on the design diagrams. The mongami with those holes are connected to make it look like a caterpillar form on there. The photo on the right shows the monshi being set into a jacquard loom. It’s difficult to see in the photo, Although the jacquard is positioned quite high, whch make it a challenging task.

-

[Loom (Hata)]

This device weaves the belt’s pattern. Strings hanging vertically in the center are from the Jacquard, controlling the warp threads. The warp threads are horizontally stretched across the center, with weft threads woven through. The part called the “osa” helps align the weft threads, and it’s supported by the “kamachi”. The cylindrical part that is rolled up from the beginning of the weaving is called “chimaki.”

-

[Yarn Dyeing]

Before weaving, the yarn will be dyed according to the pattern’s color scheme. Unlike dyeing fabrics directly, weaving patterns are created by interlacing colored weft threads. Yarn dyeing is a critical process for patterned textiles, requiring precise color matching and extensive knowledge and experience due to the complexities of pre-dyed textiles.

-

[Winding the Dyed Yarn]

Once dyed, the yarn is organized and wound for use. This makes it easier to handle during the warping and weft winding processes.

-

[Weaving the Pattern (Shuttle)]

The dyed yarn is then loaded onto shuttles, called “huki” in Japanese, and used to weave the pattern. The photo shows the “takekan” or bamboo tubes used in this process. The more shuttles used, the more complex and multicolored the fabric becomes.

-

[Weaving (Weaving Process)]

The pattern is woven by moving the “huki” left and right, creating the design. The loom has several foot-operated bars, called “fumiki,” which move the heddles, controlling the warp threads to interlace the weft. The right-hand photo shows a summer obi being woven using a “wet-releasing” method, which involves keeping the tube wet to ensure the threads interlace neatly, producing beautifully aligned sheer or gauze textiles.

-

[Completion]

This is the culmination of years of experience and skill by the weaver, producing exquisite pieces. While the belts and kimonos may seem commonplace, they represent significant investments of time and effort, continuing and preserving Japanese tradition and culture through skilled craftsmanship. Please cherish the items you currently own or plan to acquire forever. For more information, please visit the Nishijin Textile Industrial Association website.